Shelling out for World War II

By 1934 finances began to turn around again and gradually improved until 1939 when World War II began. The Second World War brought new opportunities for the Mill. The Commonwealth Air Training Scheme required multiple Air Training Bases to be built across Canada. These temporary buildings needed reinforcing bars, bolts, tie rods, and other steel items, all of which were supplied from Selkirk on orders from the Manitoba Bridge & Engineering Works and other western plants.

Additionally, the Dominion Bridge Company secured several large contracts for shell casings, and the billets for these were manufactured in Selkirk. Large amounts of steel were shipped to Vancouver and Victoria for shipbuilding. Much of the material was supplied from the Calgary plant which was re-activated in 1941 after being shut down in 1933. The demand for materials triggered the Mill to increase production yet again with the investment of a 3-ton-per-hour electric furnace in 1943.

At the end of WWII, war contracts and shipbuilding orders declined, and the Calgary plant became short of work yet again. However, instead of closing it down temporarily, the decision was made to dismantle the plant entirely and ship the buildings and machinery to Selkirk in 1946. The land was then sold.

In 1944, plant employees organized a union called the Federal Rolling Mill Employees Local 120. A pension plan was implemented, creating a valuable benefit for employees. This change stabilized employment as it encouraged employees to remain on staff until retirement.

Floods and Natural Disasters

Just when things had started to normalize after WWII ended, the Red River flooded in 1950. While the Mill is situated on the high side of the river and none of its infrastructure was affected, the devastating event affected customers and employees. Customers were unable to purchase products for several months, and some employees were unable to get to work.

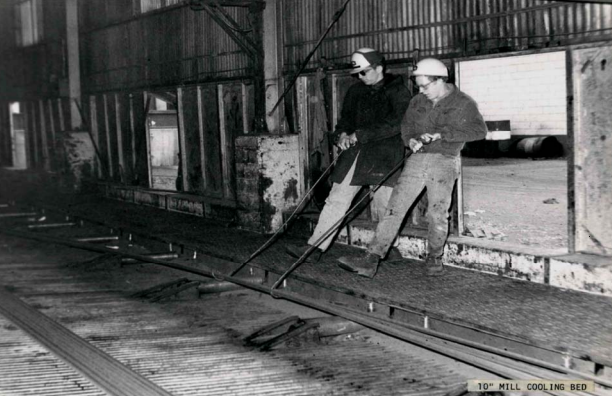

After the flood resolved, business picked up again and soon the rolling capacity had exceeded the melting capacity. A second electric furnace was needed to produce more finished products. A new 10” mill replaced the older 9” mill that had been in use since 1907.

Turmoil and Strike

In 1960, the United Steel Workers of America Local 5442 demanded that the Union have some control over the Company’s pension plan. At the same time, a new thermal generating plant was built in East Selkirk and a dispute arose about the employment of non-union workers there. Mill workers voted to strike if a solution was not reached by August. By August, the Mill had rejected the Union’s position on both issues which resulted in 400 men walking off the job for 92 days.

The strike was so momentous in Selkirk that it affected other businesses in town and accounts of vandalism increased. Emotions ran high, dividing friends and families as everyone took sides. For some families, this event changed them forever, with contentions so strong they stopped speaking to one another all together.

When the men finally returned to work, 300 hundred men had to be laid off until the spring as orders had been canceled and new business stalled because of the strike. Competition was fierce with other steel manufacturers and there was simply no work available.

Fortunately, the Manitoba Power Commission’s hydro-electrical project at Grand Rapids began and most of the mill workers were then rehired to provide steel for the project.

The strike’s financial impact on the Mill was so significant that the decision was made in 1961 to sell all the Manitoba Rolling Mill property, assets, and business to the Dominion Bridge Company Limited. From August 1st, 1961, the Mill operated as a division of the Dominion Bridge Company.

Keeping Up

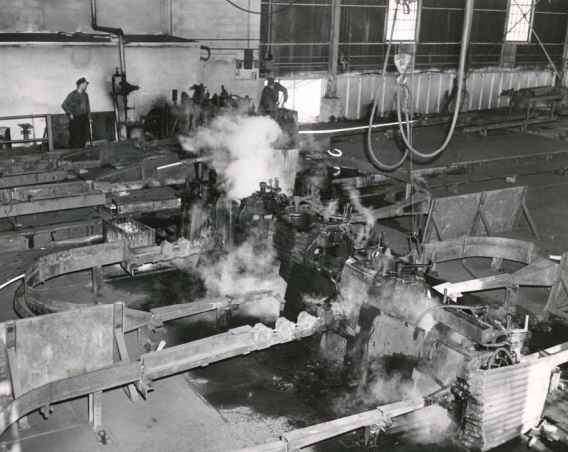

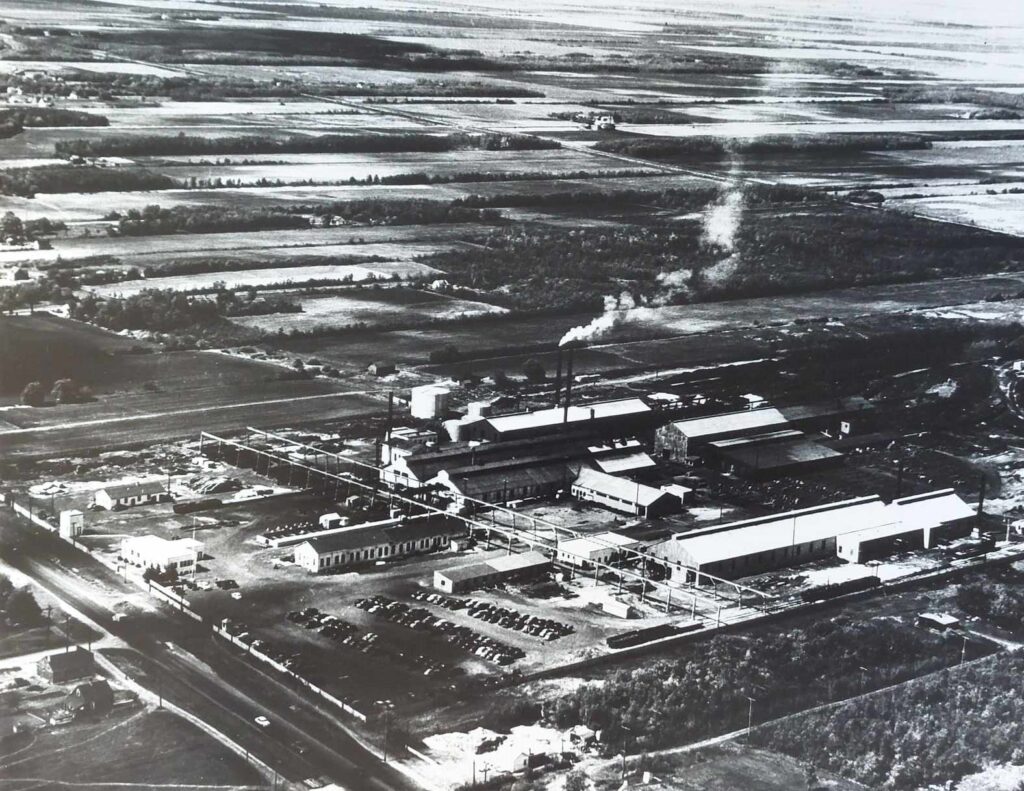

Once on the other side of the 1960s strike, the Mill experienced boom years in 1965 and 1969. A new, larger furnace building was constructed to house 2 new 40-ton electric furnaces. Once the new furnaces were operating the old open-hearth furnaces were dismantled and the open-hearth building was converted to a warehouse.

Then the Mill was met with an ultimatum. Modernize, or get left behind. A massive multi-million-dollar modernization project began, funded by the Provincial and Federal governments, the Mill, and the United Steel Workers of America Union.

Some improvements introduced at the Mill were new melting and casting facilities complete with the best technological advancements in the steel industry. From these changes, the total steel making capacity rose to 160 000 tons per year, a 75% increase from before.

Scientists, like Trevor Elderfield were hired from England to be the technician for spectrograph analysis, which would analyze the steel prior to being poured. Working conditions were improved with more ventilation, heating, and the installation of a dust collection system.

“Work will be cleaner, more facilities provided for personal comfort, less manual labour, and more opportunity to apply technical abilities.” – Selkirk Enterprise 1966.

However great the modernization program was for progress and working conditions, it affected employees in another way too. Some new jobs would be created, and some eliminated. A joint planning committee of union-management and government representatives was formed to retrain employees in new positions and relocate the 100 men who were laid off. The Selkirk Enterprise notes that despite the layoffs, “labour harmony was retained in the process.”

More improvements came in 1967 with the construction of a new melt shop. The melt shop had two-strand casters which made billets for reheating and rolling into steel as opposed to the previous open-hearth system which produced ingots.

Science and Steel

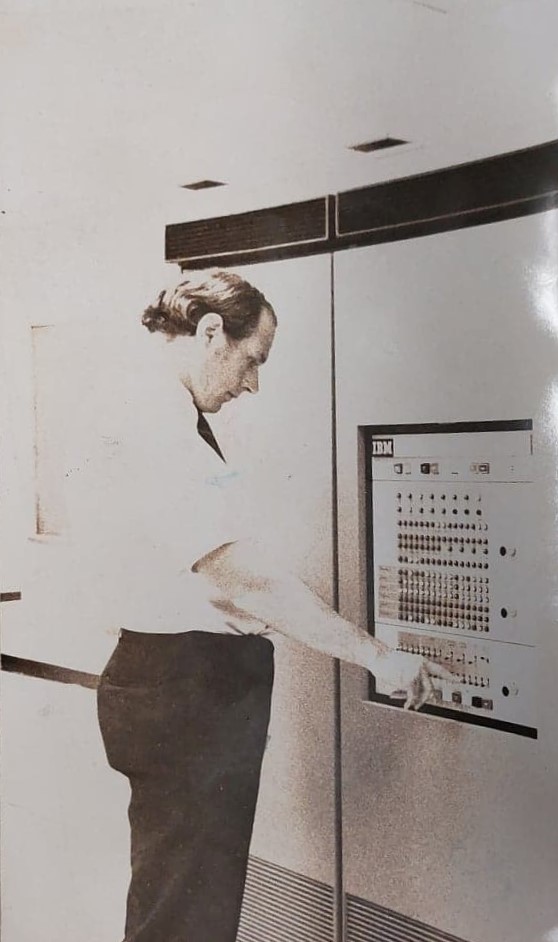

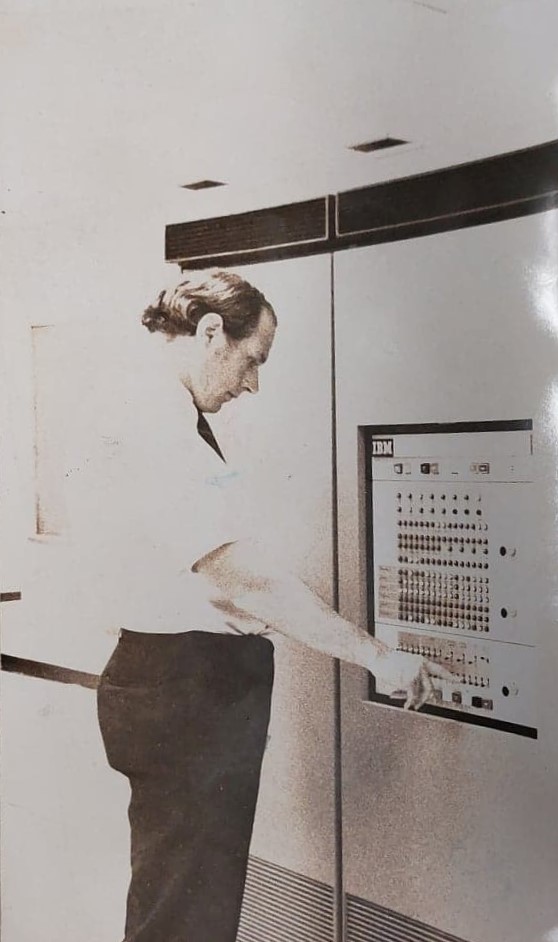

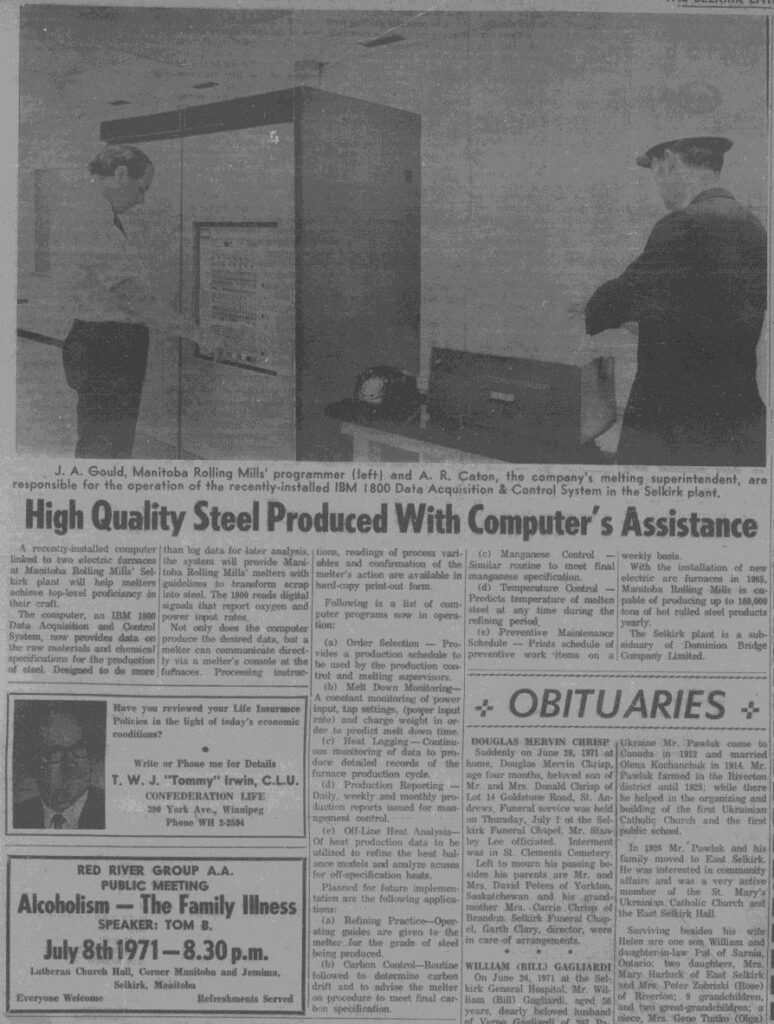

The technological advancements didn’t stop in the 1960s, by 1971, a new computer linked to two electronic furnaces was installed. The IBM 1800 Data Acquisition and Control System provided data on raw materials and chemical specifications for steel production.

Not only does the computer produce the desired data, but a melter can communicate directly via a melter’s console at the furnaces, processing instructions, readings of process variables and confirmation of the melter’s actions are available in hard-copy print-out form.

Aside from computers, the main mill used today, Number 4 Mill, was completed in 1975 and then Number 5 Mill was completed later.

In 1988, Mandak Metal Processors acquired the Manitoba Rolling Mills. After the merger, Garry Leach, the previous Manager at Mandak became President and General Manager of the Mill. Garry brought ideas of producing specialized steel products such as elevator guide rails and front-end loader cutting blades. This allowed the Mill to be independent from the peaks and troughs of the market and reduced the need for layoffs.

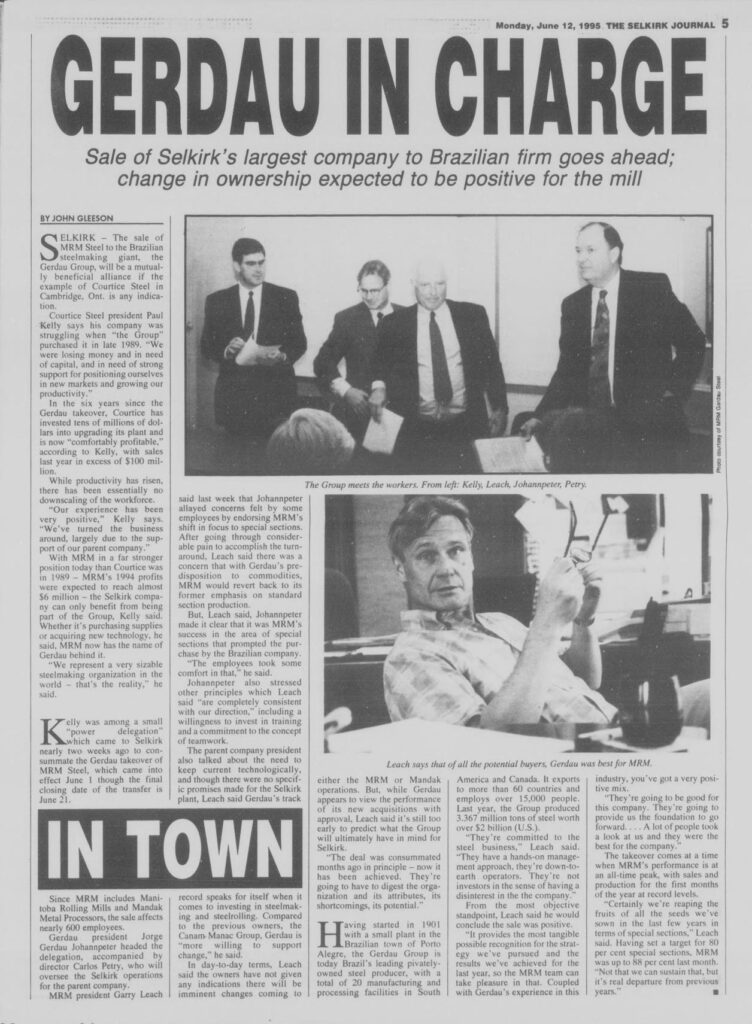

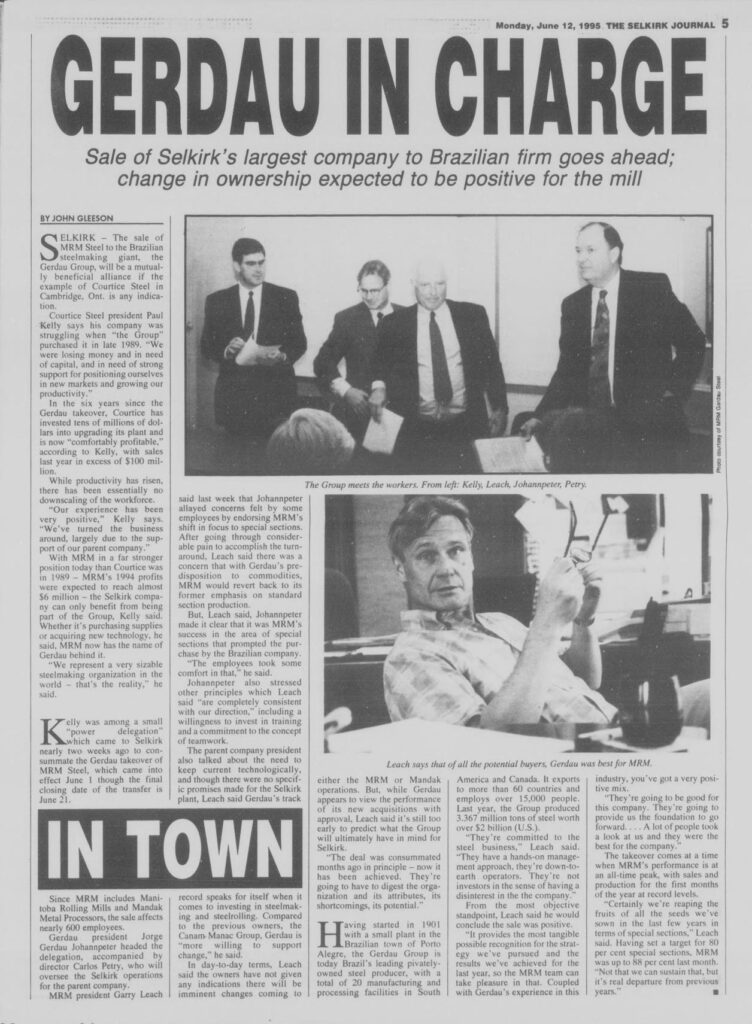

Becoming Gerdau

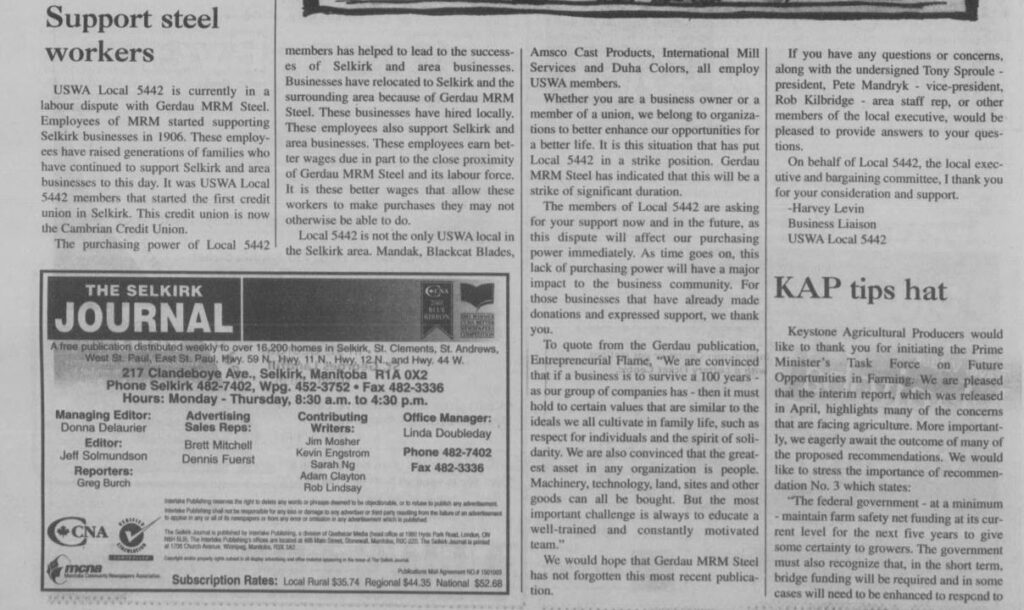

The Mills’ success prompted a company purchase by the Brazilian company, Gerdau, on June 1st, 1995. Gerdau is a leading global steel producer with a rich history like that of the Manitoba Rolling Mills. The sale affected nearly 600 employees, however, the move to sell to Gerdau proved to be a great one.

“The Selkirk company can only benefit from being part of the Group. Whether its purchasing supplies or acquiring new technology, the MRM now has the name Gerdau behind it.” Kelly – Selkirk Journal, 1995.

In 2002, the Mill underwent another labour dispute with the USWA Local 5442. Employees were still required to go to work as they were members of staff and not the Union. Workers had to park behind the front office and not along the front fence in their usual spot. They also had to remain on site for the entirety of the day, so lunches were ordered in. The strike was not as severe as the one in 1960, but it brought back many memories for some.

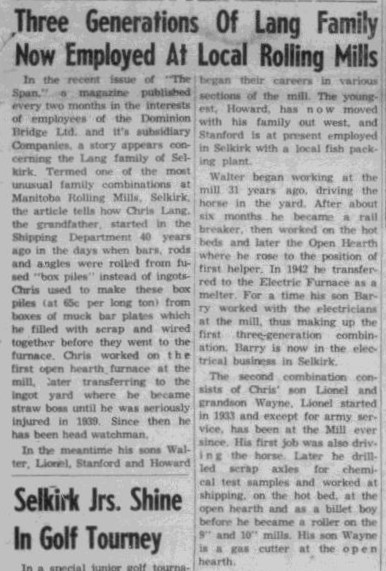

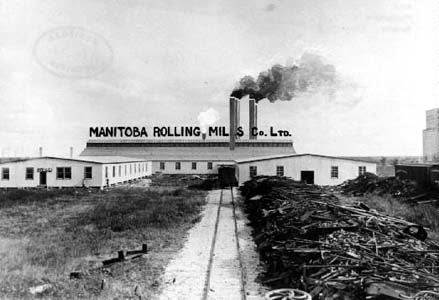

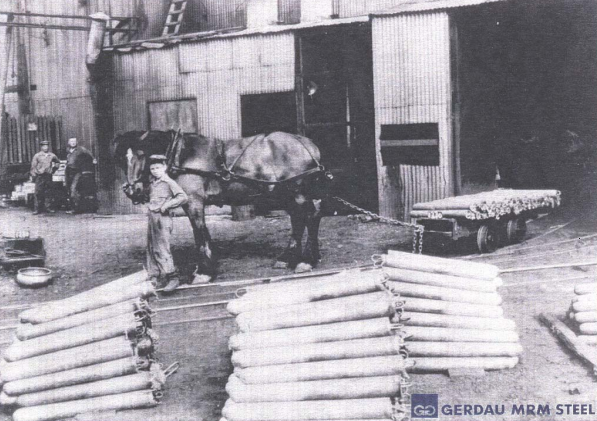

The Manitoba Rolling Mills, known today simply as Gerdau, is one of the oldest businesses in Selkirk. The Mill provided jobs for hundreds of men, often generations of employees from the same families and contributed to the Selkirk’s economy over the last century. The Mill has seen nearly every decade since Selkirk’s incorporation and continues to be a thriving business today.

Today the Mill in Selkirk manufactures world-class products using a highly-efficient electric arc furnace. Gerdau has one of the greenest footprints in the steel industry. End of life vehicles, appliances, and other sources of scrap metal is transformed into new steel products, used in transportation, agri-business, mining equipment, and in the construction of buildings.

Manitoba Rolling Mills Collection

Sources

Gerdau Website

Manitoba Business: Manitoba Bridge & Iron Works – Manitoba Historical Society

Selkirk the First Hundred Years, Barry Potyondi

Selkirk’s 75th Anniversary, Elsie MacKay, ed.

Stories of Selkirk’s Pioneers and Their Heritage, Kenneth G. Howard

Selkirk Enterprise 1956, 1966, 1971

Selkirk Journal, 1995, 2002

Oral History Interview with Peter Hall

Gerdau History Letter

A Short History of Manitoba Rolling Mill Co. LTD.